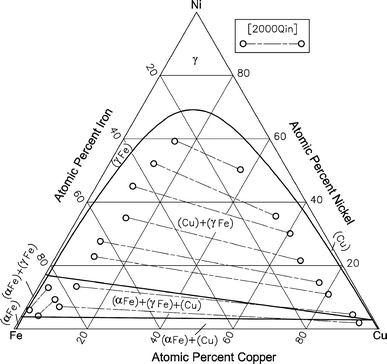

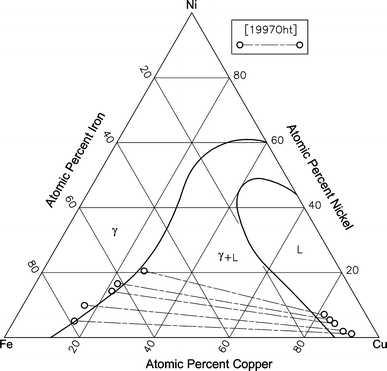

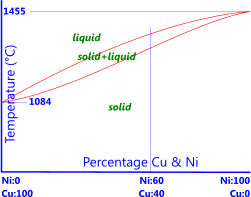

42 nickel copper phase diagram

Lag Phase Is a Distinct Growth Phase That Prepares ... 07.09.2011 · Lag phase represents the earliest and most poorly understood stage of the bacterial growth cycle. We developed a reproducible experimental system and conducted functional genomic and physiological analyses of a 2-h lag phase in Salmonella enterica serovar Typhimurium. Adaptation began within 4 min of inoculation into fresh LB medium with the … en.wikipedia.org › wiki › Solar_cellSolar cell - Wikipedia Copper indium gallium selenide (CIGS) is a direct band gap material. It has the highest efficiency (~20%) among all commercially significant thin film materials (see CIGS solar cell ). Traditional methods of fabrication involve vacuum processes including co-evaporation and sputtering.

Stationary Engine Parts Stationary Engine Parts Ltd is the largest UK stock holder of spare parts for vintage stationary engines and associated components. Supplying Lister, Petter, Wolseley, Ruston, Villiers and Jap engine spares as well as being the parent company of Paragon Paints, retailer of ultra high quality enamel paint finishes. We can cater for most of your stationary engine spare parts, ancillary …

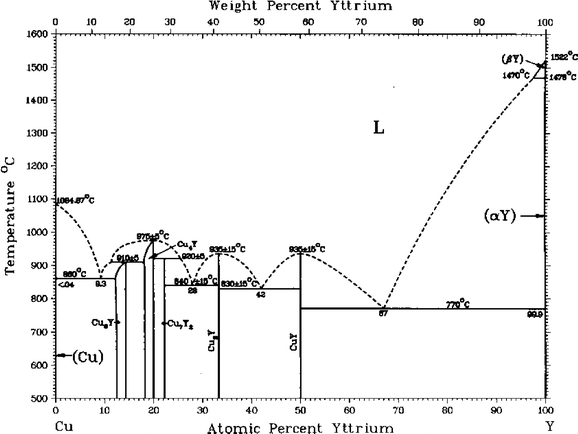

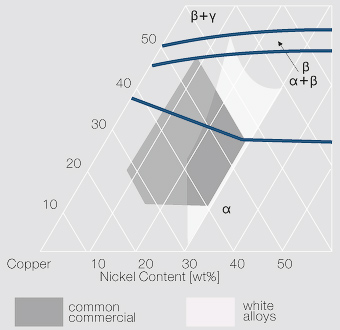

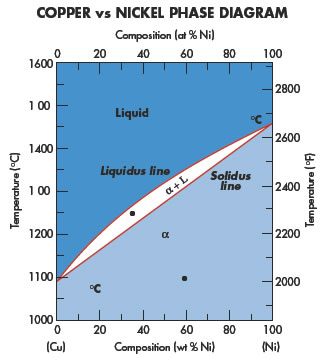

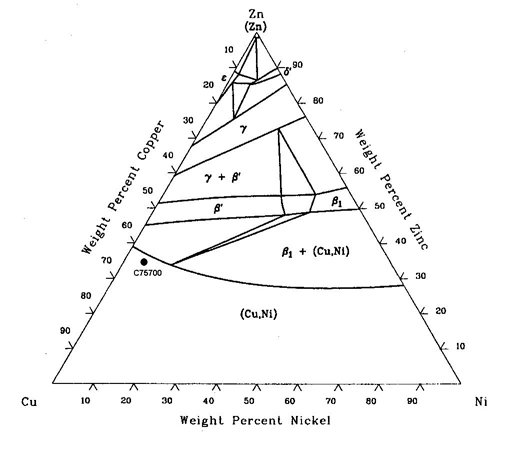

Nickel copper phase diagram

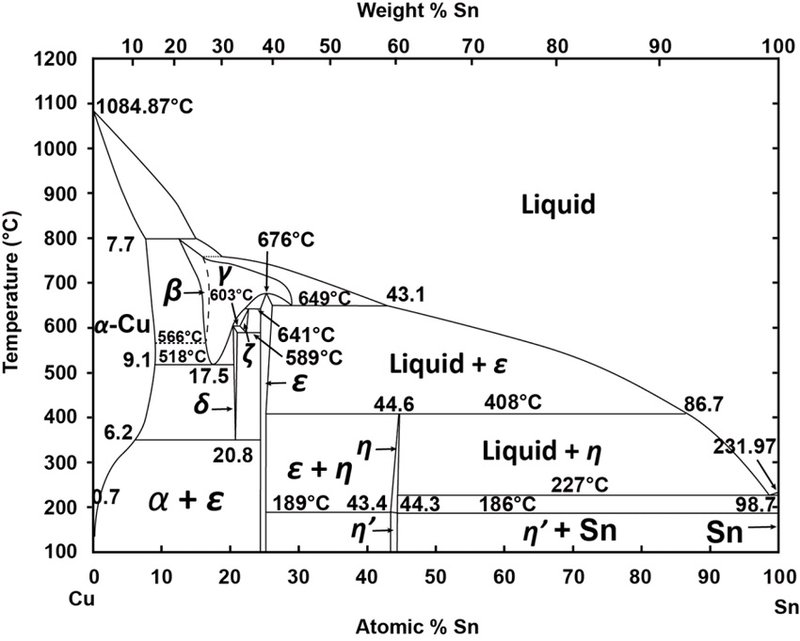

Standards & Properties: Metallurgy of Copper-Base Alloys The copper-tin equilibrium phase diagram (Figure 3) illustrates Cases (1) and (2). Figure 3. Copper-tin equilibrium phase diagram (Reference 2). Case (1) - Substitution . Figure 4. Microstructure of a single-phase (alpha) copper-tin alloy (88Cu-8Sn-4Zn). Structure shows slip lines. Note also traces of the delta phase (darker islands) (Reference 2). Referring to Figure 3, … Alloy - Wikipedia An alloy is a mixture of chemical elements of which at least one is a metal.Unlike chemical compounds with metallic bases, an alloy will retain all the properties of a metal in the resulting material, such as electrical conductivity, ductility, opacity, and luster, but may have properties that differ from those of the pure metals, such as increased strength or hardness. phys.org › news › 2022-02-scientists-quantum-phaseScientists discover quantum phase transition in pressurized ... Feb 21, 2022 · The left panel is a normalized phase diagram that is built on the basis of the experimental phase diagrams (the right panels). Credit: IOP As a result, the system should become more metallic ...

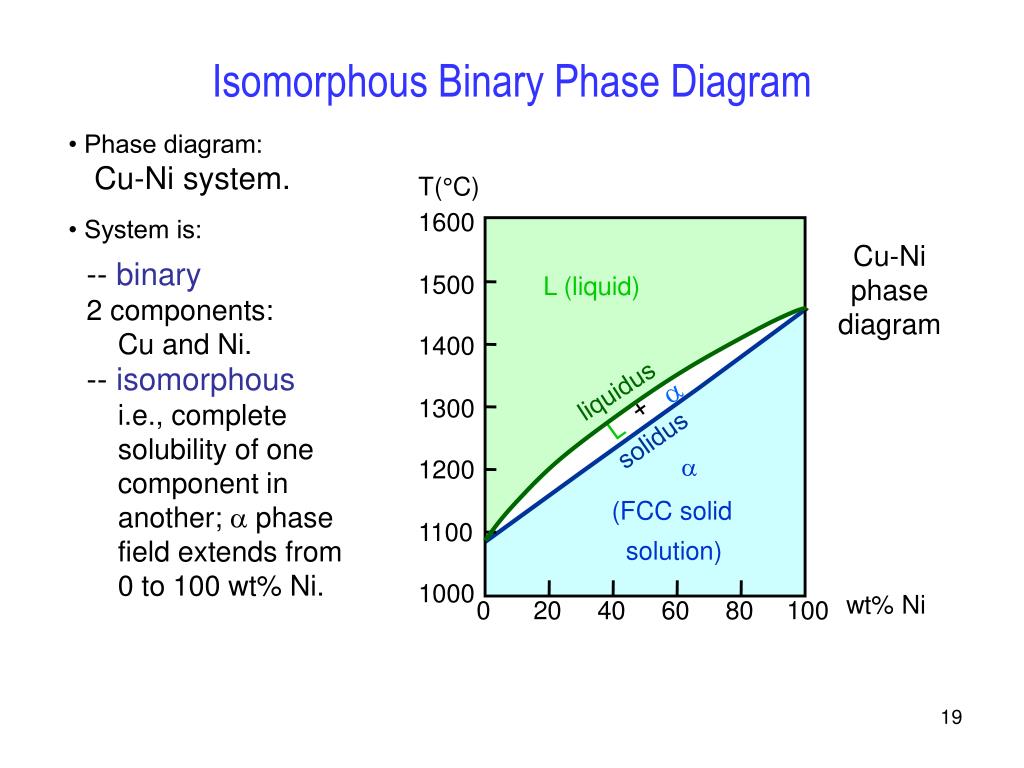

Nickel copper phase diagram. Widmanstätten pattern - Wikipedia Phase diagram explaining how the pattern forms. First meteoric iron is exclusively composed of taenite. When cooling off it passes a phase boundary where kamacite is exsolved from taenite. Meteoric iron with less than about 6% nickel (hexahedrite) is completely changed to kamacite. Widmanstätten pattern, metallographic polished section. Iron and nickel form homogeneous … Cummins V-555 & VT-555 "Triple-Nickel" V8 Diesel Engine ... The 555 cubic inch engine quickly becoming known as the “Triple-Nickel”. These engines proved to be barely sufficient when powering pumps, generators, and farm equipment provided they were not lugged, heavily loaded, or quickly accelerated. unfortunately, the fuel crisis of the early 1970’s resulted in these engines, especially the 555, being misfitted to medium duty trucks and school ... Chapter 11: Phase Diagrams Chapter 11: Phase Diagrams. Phase B. Phase A. Nickel atom. Copper atom ... Cu-Ni phase diagram. Isomorphous Binary Phase Diagram. • Phase diagram:.42 pages Metal-organic framework derived carbon-supported ... The crystalline phase of the as-prepared catalysts was ... The above spectroscopic and microscopic characterizations collectively demonstrate that the copper-nickel alloys encapsulated in nitrogen-doped graphene shell could be prepared through the direct high temperature pyrolysis of bimetallic MOF precursors under inert atmosphere. The alloy …

Hydrogen Embrittlement - an overview | ScienceDirect Topics Certain metals (e.g., iron, titanium, and nickel) are more susceptible to HE than others (e.g., copper, aluminum, and austenitic stainless steel). Removal of the metal from the source of hydrogen and heat treatment (to about 200°C) restores its mechanical properties. Therefore it is assumed that HE is caused by hydrogen atoms when they do not combine to form hydrogen … mp-30: Cu (cubic, Fm-3m, 225) - Materials Project Cu is Copper structured and crystallizes in the cubic Fm-3m space group. The structure is three-dimensional. Cu is bonded to twelve equivalent Cu atoms to form a mixture of corner, edge, and face-sharing CuCu12 cuboctahedra. All Cu–Cu bond lengths are 2.56 Å. Metallurgy of Titanium and its Alloys Metallurgy of Titanium and its Alloys H. K. D. H. Bhadeshia Pure Titanium. Pure titanium melts at 1670 o C and has a density of 4.51 g cm-3.It should therefore be ideal for use in components which operate at elevated temperatures, especially where large strength to … phys.org › news › 2022-02-scientists-quantum-phaseScientists discover quantum phase transition in pressurized ... Feb 21, 2022 · The left panel is a normalized phase diagram that is built on the basis of the experimental phase diagrams (the right panels). Credit: IOP As a result, the system should become more metallic ...

Alloy - Wikipedia An alloy is a mixture of chemical elements of which at least one is a metal.Unlike chemical compounds with metallic bases, an alloy will retain all the properties of a metal in the resulting material, such as electrical conductivity, ductility, opacity, and luster, but may have properties that differ from those of the pure metals, such as increased strength or hardness. Standards & Properties: Metallurgy of Copper-Base Alloys The copper-tin equilibrium phase diagram (Figure 3) illustrates Cases (1) and (2). Figure 3. Copper-tin equilibrium phase diagram (Reference 2). Case (1) - Substitution . Figure 4. Microstructure of a single-phase (alpha) copper-tin alloy (88Cu-8Sn-4Zn). Structure shows slip lines. Note also traces of the delta phase (darker islands) (Reference 2). Referring to Figure 3, …

![1 Phase diagram of copper nickel system [88]. | Download ...](https://www.researchgate.net/profile/Gandham-Phanikumar/publication/307963440/figure/fig14/AS:404634498813953@1473483790439/Phase-diagram-of-copper-nickel-system-88_Q640.jpg)

![Sn-Cu-Ni phase diagram [7]. | Download Scientific Diagram](https://www.researchgate.net/publication/317967778/figure/fig3/AS:510292191072256@1498674547588/Sn-Cu-Ni-phase-diagram-7.png)

![6. Cu-Ni binary phase diagram [96]. | Download Scientific Diagram](https://www.researchgate.net/profile/Yong-Zhang-116/publication/259887707/figure/fig10/AS:614382572670993@1523491628748/Cu-Ni-binary-phase-diagram-96.png)

Comments

Post a Comment